UHV Leakvalves - Technical Specification

This specification applies to all versions of the leakvalves, manual, motor driven and pneumatically controlled.

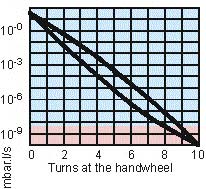

In the range of turn 0 - 3 the diaphragm

does not touch the valve seat. Due to

physical reasons, control between

10 E-9 And 10 E-10 is not possible, if

used at room temperature (red range

in the diagram). In this case the valve

is tight approx at turn 9 to 10. Control

in this range is possible if the valve

is heated.

Maximum throughput is 60 mbar.l/s

For more information

email carl@crc-technology.com

| Material housing | 316L |

| Material diaphragm | 316L, gold plated |

| Material outside of vacuum | 304, protected steel |

| Lifetime | 100,000 cycles until first service |

| Mounting position | any |

| Weights: | |

| handoperated CF 16/16 | 1.6 kg |

| handoperated CF 35/16 | 2.2 kg |

| handoperated VCR | 1.5 kg |

| motor driven | manual + 2.3 kg |

| pneumatically operated NC | manual + 8.6 kg |

| Internal pressure | Vacuum to 10 bar |

| Pressure difference | 10 bar from each side |

| Baking temperatures: | |

| Valve open | 450°C |

| Valve closed or operable | 300°C |

| Tightness housing | 1.10 E-10 mbar.l.s-1 |

| Tightness valve seat | 1.10 E-10 mbar.l.s-1 |

| Dead volumes: | |

| Main flange side | 1.0 - 1.4 cm3 |

| Side flange side | 4.6 cm3 |

| Turns of the handwheel | 10 |

| Operating time motor driven | 10 seconds for the whole range |

| Compressed air pneumatic cylinder | 4 - 9 bar overpressure |