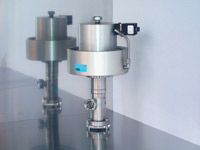

UHV Leakvalve - Pneumatically Operated

The pneumatically actuatated version of the leakvolve can switch quickly and easily between the closed and a freely adjustable open position. Without pressure the valce is closed (NC). The adjustment of the open position is done with a set screw on top of the pneumatic cylinder.

The housing and all parts in touch with the medium are made of stainless steel. The plate gasket and the bonnet gasket are one piece and made of stainless steel, gold plated. The tightening between the valve rod and the inner volume is done through a diaphragm made of metal.

A pneumatic cylinder operates the valve, which is assembled to the valve by using a teflon part for thermic isolation. It is important to keep the temperatures of the actuator under 120°C, and of the solenoid valve under 80°C.

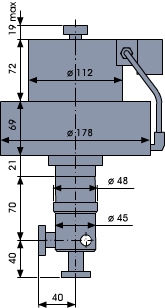

The adjustable open position can be fixed over the whole control range. If there is a distance of 1mm between the screwhead (hexagon 24mm) and the cylinder cap (flat surface), the closed position is adjusted. If this gap is 9mm or more, the full open position is adjusted. The nominal stroke of this screw is 8mm = 4 full turns. This screw is self-locking.

The actuator is greased for life. If the cylinder should be disassembled for any reason, a simple tool is necessary. This simple tool is a screw M8 in the right length and a washer, we will provide you with the necessary dimensions.

For more information email carl@crc-technology.com

| Pneumatic Pressure | 4 to 9 bar overpressure |

| Solenoid Valve | mounted 24VDC; 4.5W |

| Operating time to open position | <1s |

| Adjustment Screw | M24; 4 turns for the whole stroke |